Summary: In the dynamic landscape of nonwove...

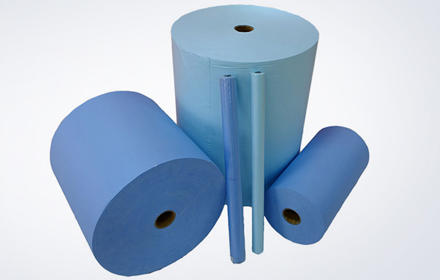

In the dynamic landscape of nonwoven fabrics, spunlace nonwovens have carved a niche for themselves, finding applications in various industries. Behind the success of spunlace nonwovens lies a network of dedicated suppliers, each contributing to the innovation and versatility of these fabrics. This article explores the significance of spunlace nonwoven suppliers, shedding light on their role in providing cutting-edge solutions to diverse sectors.

Spunlace nonwoven suppliers play a pivotal role in the manufacturing process, leveraging advanced technologies to produce these unique fabrics. The production involves high-pressure water jets that entangle fibers, creating a fabric with exceptional strength, softness, and absorbency. Suppliers with expertise in the intricacies of spunlace technology are essential for ensuring the quality and performance of the final nonwoven product.

Spunlace nonwovens find applications across a broad spectrum of industries, from healthcare and personal care to automotive and industrial sectors. Suppliers cater to the diverse needs of these industries by offering a range of spunlace nonwoven products tailored to specific applications. This versatility positions spunlace nonwoven suppliers as key contributors to innovation and problem-solving in various fields.

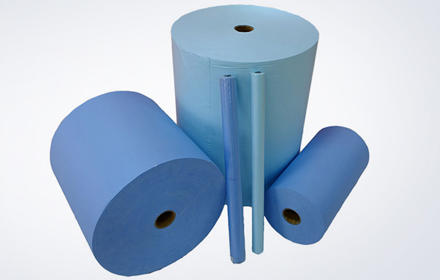

Leading spunlace nonwoven suppliers understand the importance of customization to meet the unique requirements of different industries. These suppliers offer a variety of options in terms of fiber composition, weight, and surface characteristics. The ability to tailor spunlace nonwoven fabrics to specific needs demonstrates a commitment to innovation and ensures the material's suitability for diverse applications.

Spunlace nonwoven suppliers prioritize quality assurance and compliance with industry standards. Rigorous testing processes are implemented to assess the strength, durability, and performance of the fabric. Compliance with regulations, such as those governing medical textiles or automotive components, is a crucial aspect that reputable suppliers adhere to, ensuring the safety and reliability of the spunlace nonwoven products they provide.

As sustainability gains prominence in the textile industry, spunlace nonwoven suppliers are actively embracing eco-friendly practices. Many suppliers are incorporating recycled fibers and implementing efficient production processes to reduce environmental impact. By prioritizing sustainability, spunlace nonwoven suppliers contribute to the development of a more environmentally conscious supply chain.